TECHNOLOGY

Multi-Phase Extraction (MPE)

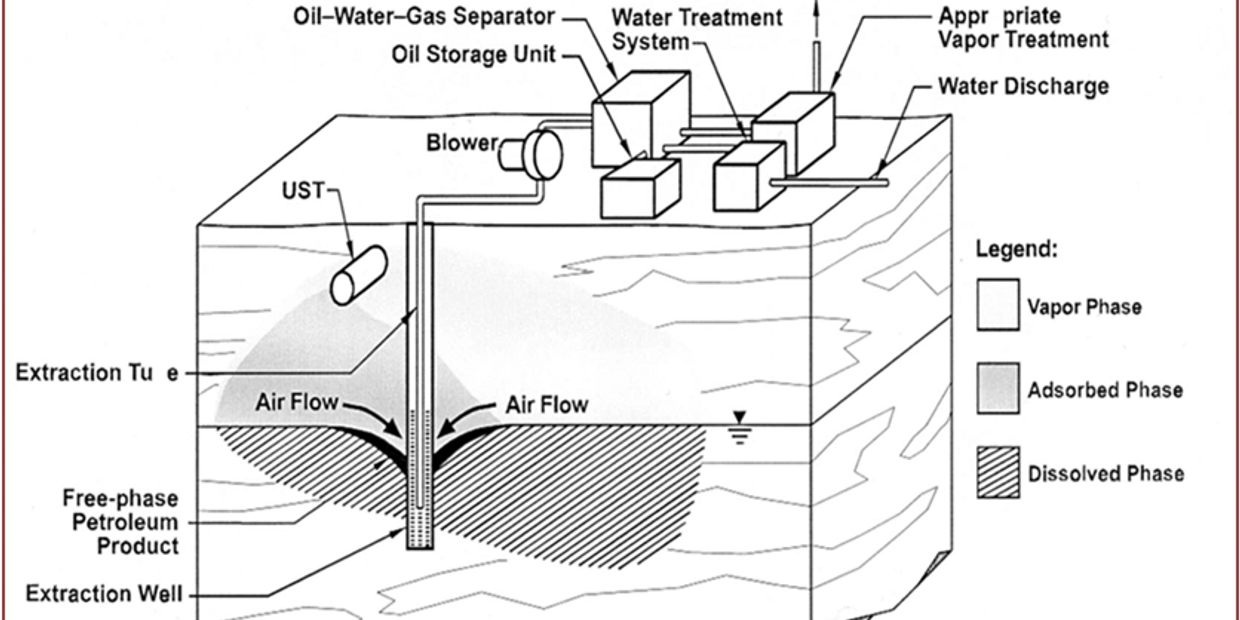

Multi-phase extraction (MPE), also known as Dual Vapor Extraction (DVE), Dual-Phase Extraction (DPE), vacuum-enhanced extraction, or sometimes bioslurping, is an in-situ technology that uses pumps or entrainment (slurping) to remove various combinations of contaminated groundwater, separate-phase petroleum product, and hydrocarbon vapor from the subsurface. Extracted liquids and vapor are treated and collected for disposal, or re-injected to the subsurface (where permissible under applicable state laws).

Multi-phase extraction also allows for dewatering the saturated zone, exposing the previously saturated zone to air flow from soil vapor extraction (SVE).

Application

MPE systems can be effective in removing separate-phase product (free product) from the subsurface, thereby reducing concentrations of petroleum hydrocarbons in both the saturated and unsaturated zones of the subsurface. MPE systems are typically designed to maximize extraction rates; however, the technology also stimulates biodegradation in the unsaturated zone by increasing the supply of oxygen, in a manner similar to that of bioventing.

Multi Phase Extraction can also be effective in remediation of a “smear zone” and capillary fringe in the subsurface. Contaminant can become trapped adsorbed to soil below the groundwater due to fluctuations of the groundwater table. A “smear zone” can be formed when free floating product (free product) is “smeared” along the soil due to the fall and subsequent rise of the water table.

MPE is often selected because it enhances groundwater and/or product recovery rates, especially in layered, fine-grained soils. The application of MPE also maximizes the effectiveness of soil vapor extraction (SVE) by lowering the water table and therefore increasing air-phase permeability in the vadose zone.

Operation Principles

The vacuum applied to the subsurface with MPE systems creates vapor-phase pressure gradients toward the vacuum well. These vapor-phase pressure gradients are also transmitted directly to the subsurface liquids present, and those liquids existing in a continuous phase (e.g., water and "free" petroleum product) will flow toward the vacuum well in response to the imposed gradients (the term "free" product is a commonly used, though imprecise term because a greater fraction of resident petroleum product may be recovered using vacuum-enhanced MPE compared to the fraction of product recoverable using gravity drainage alone). The higher the applied vacuum, the larger the hydraulic gradients that can be achieved in both vapor and liquid phases, and thus the greater the vapor and liquid recovery rates.

Dramatic enhancements in both water and petroleum product recovery rates resulting from the large hydraulic gradients attainable with MPE systems have been reported in the literature (Blake and Gates, 1986; Blake, et al., 1990; Bruce, et al., 1992). The depressed groundwater table that results from these high recovery rates serves both to hydraulically control groundwater migration and to increase the efficiency of vapor extraction. The remedial effectiveness of MPE within the zone of dewatering that commonly develops during MPE

application should be greater than that of air sparging due to the more uniform air flow developed using MPE (Johnson, et al., 1992).

System Design

Although this general class of technologies is broadly referred to as Multi-phase extraction, significant variations in the technology exist. MPE systems often apply relatively high vacuums to the subsurface. Thus, the adjective "high-vacuum" is sometimes used to describe MPE technologies, even though all MPE systems are not high-vacuum systems. MPE technologies can be divided into two general categories:

- subsurface liquid(s) and soil vapor are extracted together as a high-velocity Multi-phase (liquid(s) and vapor) stream using a single pump, or

- subsurface liquid(s) and soil vapor are extracted separately using two or more pumps.

Single-Pump Systems. Single-pump systems also known as entrainment or slurping) rely on high-velocity airflow to lift suspended liquid droplets upwards by frictional drag through an extraction tube to the land surface. Single-pump vacuum extraction systems can be used to extract groundwater or combinations of separate-phase product and groundwater.

Single-pump MPE systems represent a recent adaptation of the long-established technology known as "vacuum groundwater extraction". This technology has been used for many decades as a standard method for extracting groundwater to control seepage or effect dewatering during excavation, construction and mining activities.

Single-pump MPE systems are generally better suited to low-permeability conditions, and they are difficult to implement at sites where natural fluctuations in groundwater levels are substantial. United States patents exist on certain applications of single-pump MPE systems (Hess et al., 1991; Hajali et al., 1992; Hess et al., 1993).

Multi-Pump Systems. The somewhat more conventional Multi-pump systems use one pump to extract liquids from the well and a surface blower (the second pump) to extract soil vapor. A third MPE configuration uses a total of three pumps, including the surface blower together with one pump to extract floating product and one to extract groundwater. Both double- and triple-pump MPE systems extract the well liquids separately from the soil vapor and are similar in operation and application

Multi-pump MPE systems are simply a combination of traditional soil vapor extraction (SVE) and groundwater (and/or floating product) recovery systems. Multi-pump systems tend to be more flexible than single-pump systems, making Multi-pump systems easier to apply over a wider range of site conditions (e.g., fluctuating water tables, wide permeability ranges); however, equipment costs are higher.

Advantages and Disadvantages

Advantages

- Proven performance over a wide range of conditions. Requires no downhole pumps, but is flexible enough to allow their use if necessary.

- Minimal disturbance to site operations; can be used under buildings without excavation.

- Short treatment times (usually 6 months to 2 years under optimal conditions).

- Substantially increases groundwater extraction rates.

- Can be applied at sites with free product, and can be combined with other technologies.

- Can reduce the cost of groundwater treatment through air stripping within the vacuum extraction tube.

Disadvantages

- Single-pump systems are expensive to implement at sites with medium to high-permeability soils, and effectiveness. Multi-pump systems may not be effective in low permeability soils.

- Difficult to apply to sites where the water table fluctuates unless water table depression pumps are employed

- Treatment may be expensive for extracted vapors and for oil-water separation.

- Large volume of extracted groundwater may require treatment

- Requires specialized equipment with sophisticated control capability.

- Requires complex monitoring and control during operation.

References

Blake, S.B., and N.M. Gates. 1986. Vacuum Enhanced Hydrocarbon Recovery: A Case Study," in Proceedings of NWWA/API Conference on Petroleum Hydrocarbons and Organic Chemicals in Ground Water: Prevention, Detection, and Restoration. November 12-14, Houston, Texas, p. 709-721.

Blake, S., B. Hockman, and M. Martin. 1990. "Applications of Vacuum Dewatering Techniques to Hydrocarbon Remediation, in Proceedings of NWWA/API Conference on Petroleum Hydrocarbons and Organic Chemicals in Ground Water: Prevention, Detection, and Restoration. October 31 - November 2, Houston, Texas, p. 211-226.

Bruce, L., B. Hockman, R. James-Deanes, J. King, and D. Laws. 1992. Vacuum Recovery Barrier Wall System Dewaters Contaminated Aquifer: A Solution Based on Proper Evaluation of Hydrogeologic Parameters, in Proceedings of the NGWA/API Conference on Petroleum Hydrocarbons and Organic Chemicals in Ground Water: Prevention, Detection, and Restoration. November 4-6, Houston, Texas, p. 303-311.

Hajali, P.A., and W.F. Revely, III. 1992. Process and Apparatus for Groundwater Extraction Using a High Vacuum Process. U.S. Patent No. 5,172,764, December 22.

Hess, R.E., A.A. Hooper, S.R. Morrow, D.J. Walker, and E. Zimmerman. 1991. Process for Two Phase Vacuum Extraction of Soil Contaminants. U.S.Patent No. 5,050,676, September 24.

Hess, R.E., A.A. Hooper, S.R. Morrow, D.J. Walker, and E. Zimmerman. 1993. Apparatus for Two Phase Vacuum Extraction of Soil Contaminants. U.S.Patent No. 5,197,541, March 30.

Johnson, R.L., Bagby, W., Matthew, P., and Chien, C.T. 1992. Experimental Examination of Integrated Soil Vapor Extraction Techniques, in Proceedings of Petroleum Hydrocarbons and Organic Chemicals in Ground Water: Prevention, Detection, and Restoration. National Ground Water Association, November.

Powers, J.P. 1994. Construction Dewatering, A Guide to Theory and Practice. Wiley Interscience, 1981. U.S.Air Force. Technology Profile: Vacuum-Mediated LNAPL Free Product Recovery/Bioremediation (Bioslurper). Air Force Center for Environmental Excellence, March.

Downloads

Multi-Phase Extraction (MPE) (pdf)

DownloadCopyright © 2023 CES Group - All Rights Reserved.

Powered by GoDaddy